TUBALL™

单壁碳纳米管:

先进

OCSiAl is the global leader in single wall carbon nanotube technologies and the key supplier of nanotube solutions. Explore more than 40 nanotube products for various polymers and electrochemical power sources.

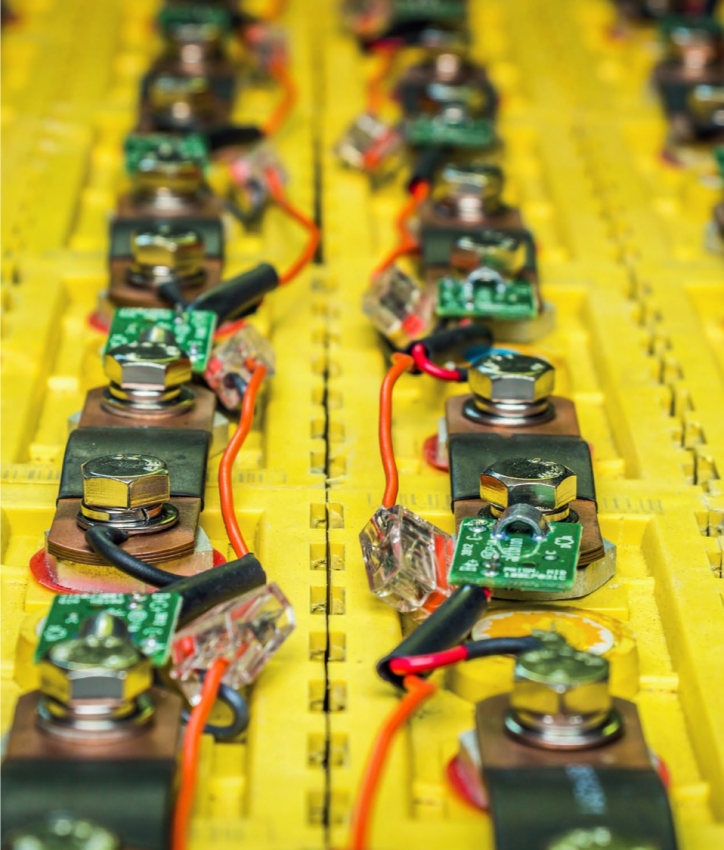

电池High-performing conductive and reinforcing additive for battery electrodesLearn more航空航天单壁碳纳米管增强的智能材料和技术了解更多石油天然气单壁碳纳米管保障安全和高效生产了解更多未来交通纳米增强交通–智能、实用和节能了解更多

应用案例

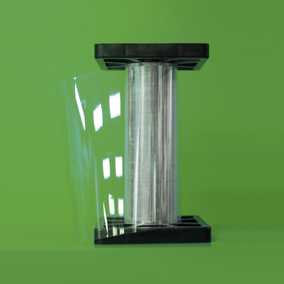

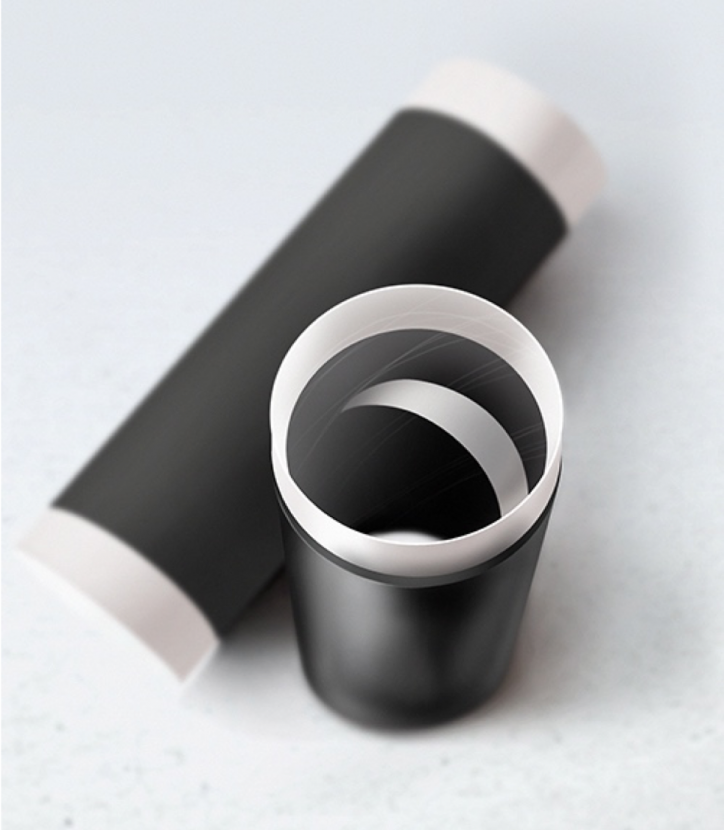

TUBALL™单壁碳纳米管硅胶柔性皮肤电极、传感器应用

产品

导电硅胶皮肤电极、传感器

要求

- 体积电阻率<10 Ω∙cm

- 柔软、高弹性材料

TUBALL™解决方案

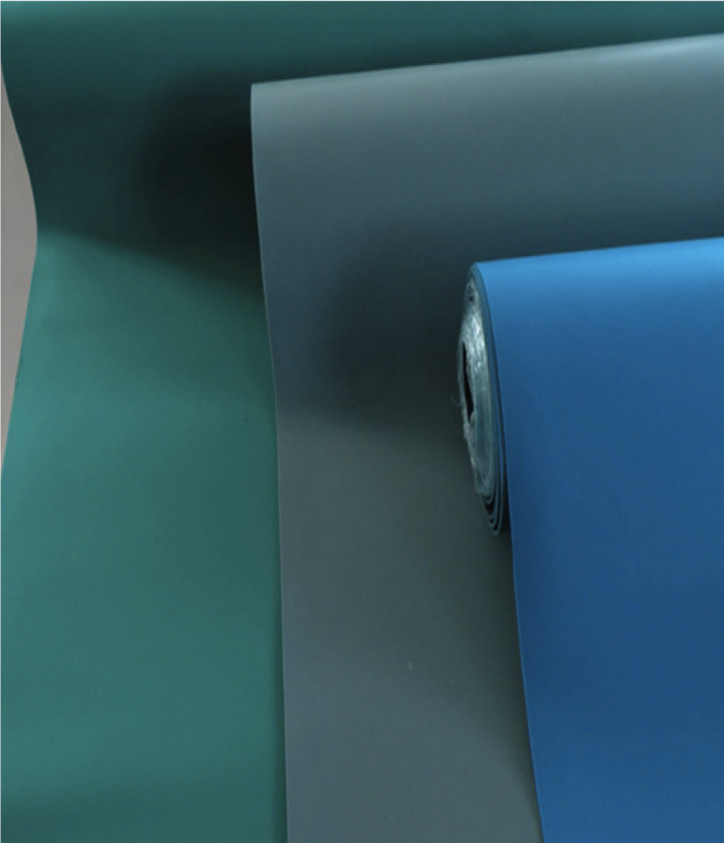

添加5%(质量比)的TUBALL™ MATRIX 613 beta

主要优势

- 体积电阻率<10-102 Ω∙cm

- 柔韧性

- 无尘生产

- 无碳释放到表面,不污染皮肤

新闻

总部

奥盛纳米科技(深圳)有限公司成立于2017年,是OCSiAl集团在中国的分公司,其单壁碳纳米管的商标为TUBALL™。

OCSiAl是全球专业的单壁碳纳米管制造商,且是拥有可扩展工业合成单壁碳纳米管技术的跨国公司。单壁碳纳米管是单层石墨烯薄片卷曲的管状结构。与标准添加剂相比,TUBALL单壁碳纳米管的优势在于其优异的导电性、导热性、强度和柔韧性。为简化单壁碳纳米管的分散,OCSiAl开发了TUBALL™ MATRIX预分散体系列产品,可以直接将单壁碳纳米管引入标准的生产工艺中,仅需要0.1%的预分散体即可显著改善材料的性能。目前,OCSiAl已开发出适用于锂离子电池、弹性体、复合材料、塑料、油漆和涂料等应用的TUBALL™技术方案。目前,OCSiAl单壁碳纳米管粉体现有和规划产能为1000吨。