用于需要溶剂的环氧树脂和聚氨酯涂料的基于塑化剂(缩水甘油醚基)的导电和抗静电添加剂,颜色和机械性能方面无缺陷。

材料系统

溶剂型环氧树脂和聚氨酯树脂。

工作剂量

0.1 – 1 % (质量比)。

载体

增塑剂和稳定剂——脂肪酸缩水甘油酯、聚烯烃衍生物铵盐。

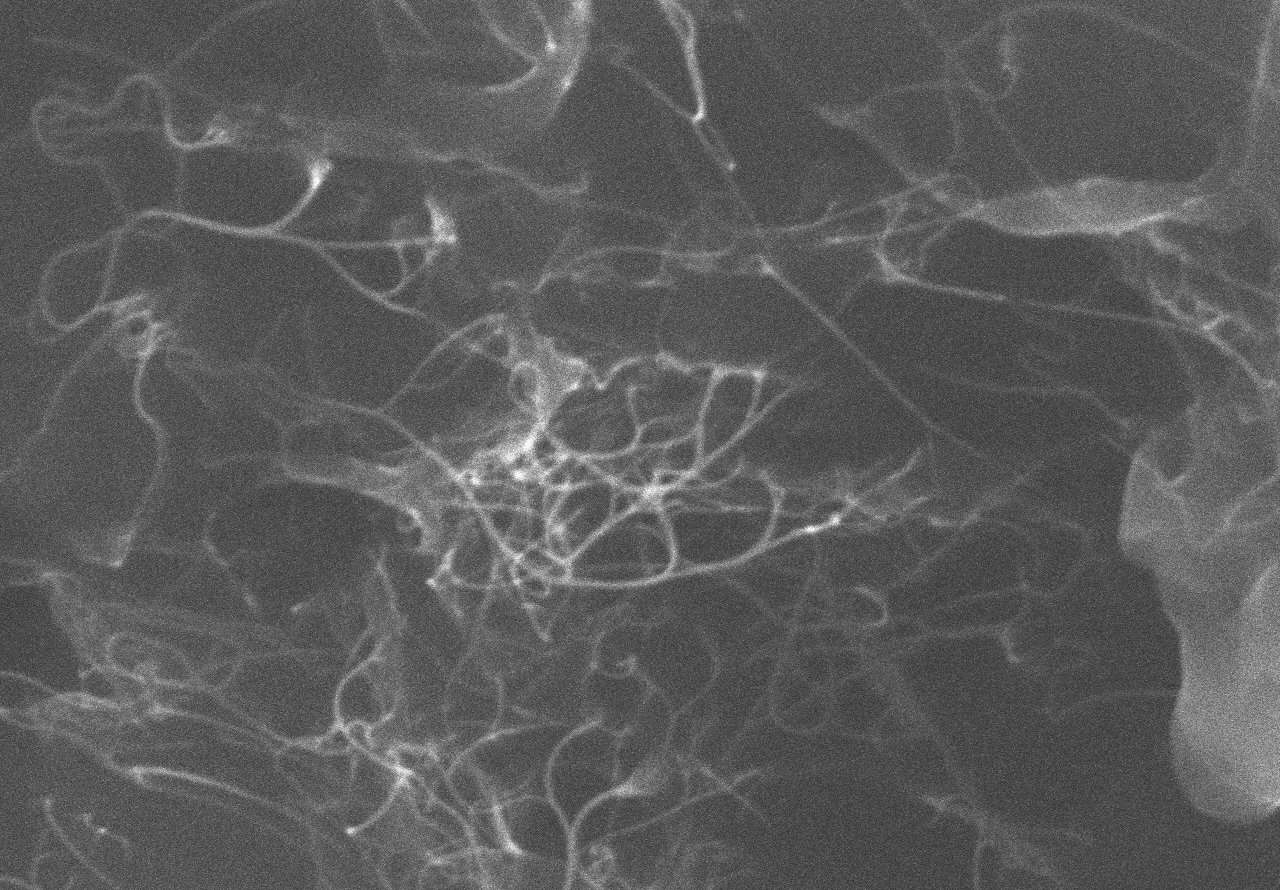

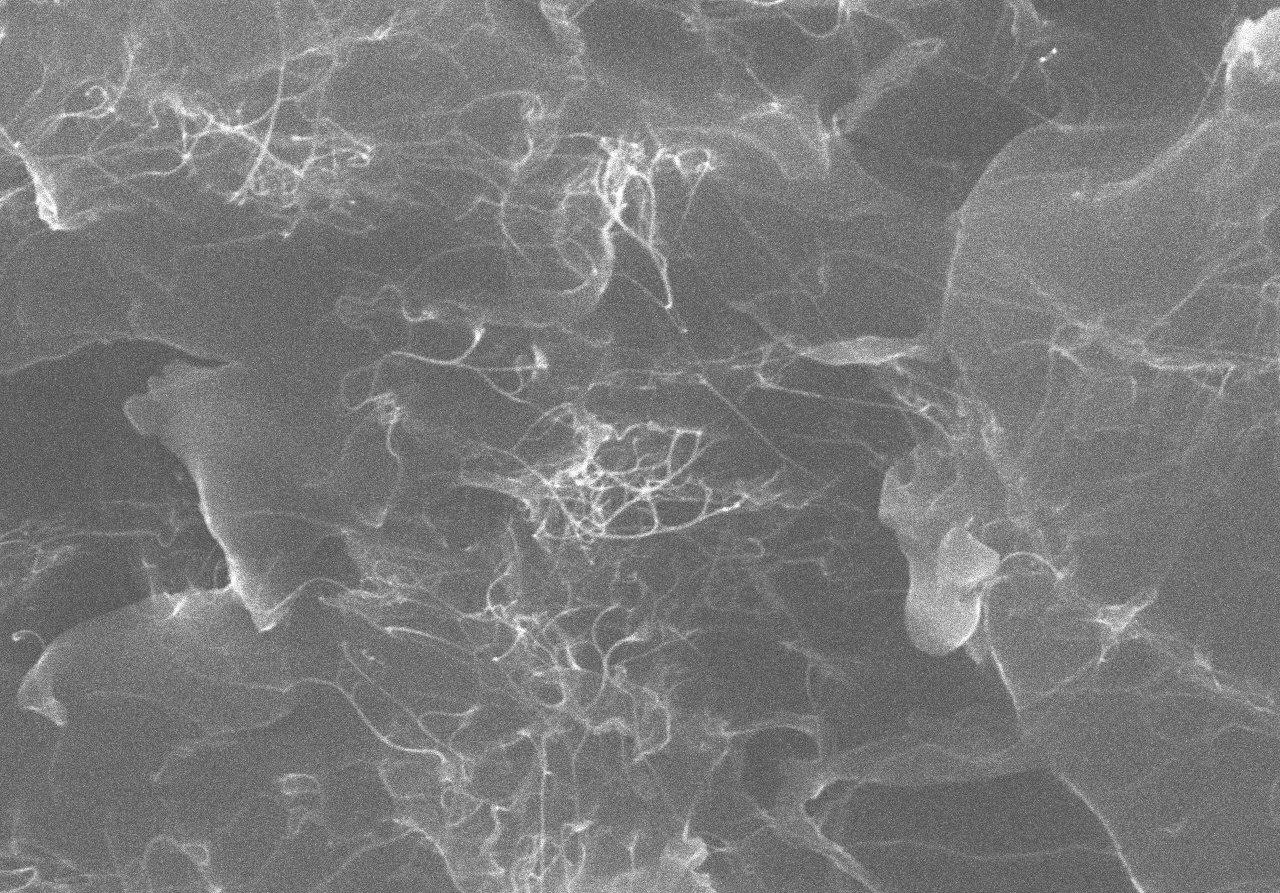

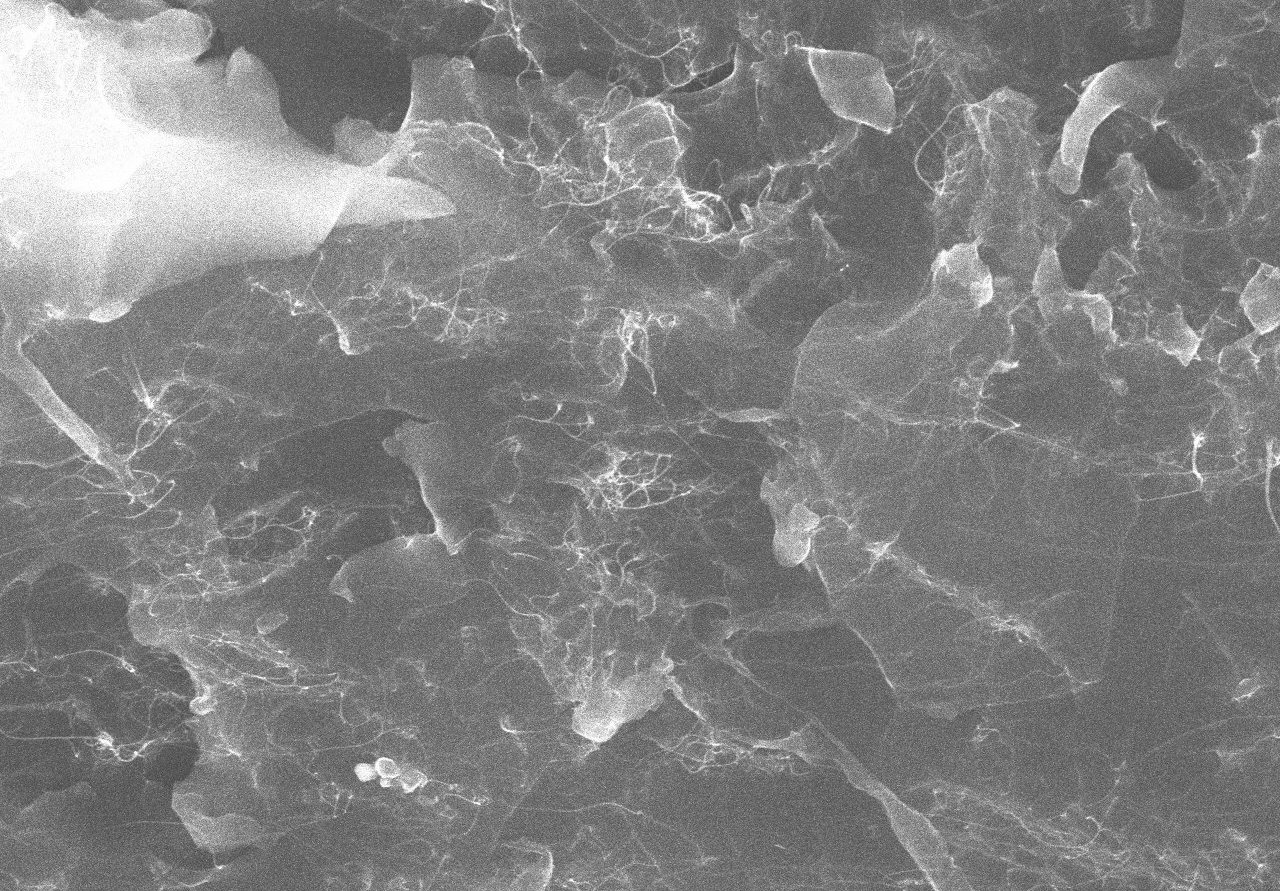

形态

膏状

主要优势

导电性

确保无“盲点”的永久均匀导电

机械性能

保持或提升机械强度

保持颜色

保持材料的浅色或亮色

使用简便

预分散体形式大大简化了单壁碳纳米管的处理,不需要改变标准的生产工艺

保持黏度

最小化对主体基材黏度和密度的影响

应用案例

用于储罐内衬涂料的

点击查看应用案例

石油储罐涂层

点击查看应用案例

视频

TUBALL MATRIX – 操作指南

资料

ALSO_AVAILABLE_IN:

English

TDS TUBALL MATRIX 203 ENG V10.PDF

PDF307.2 kB

TUBALL MATRIX 200X 300X PROCESSING GUIDELINES ENG V04.PDF

PDF512 kB

TUBALL MATRIX 200X 300X PROCESSING KEY POINTS ENG V03.PDF

PDF8 MB