TUBALL

New Perspectives in SWCNT Applications: TUBALL SWCNTs. Part 1. TUBALL by Itself – All You Need to Know about It.

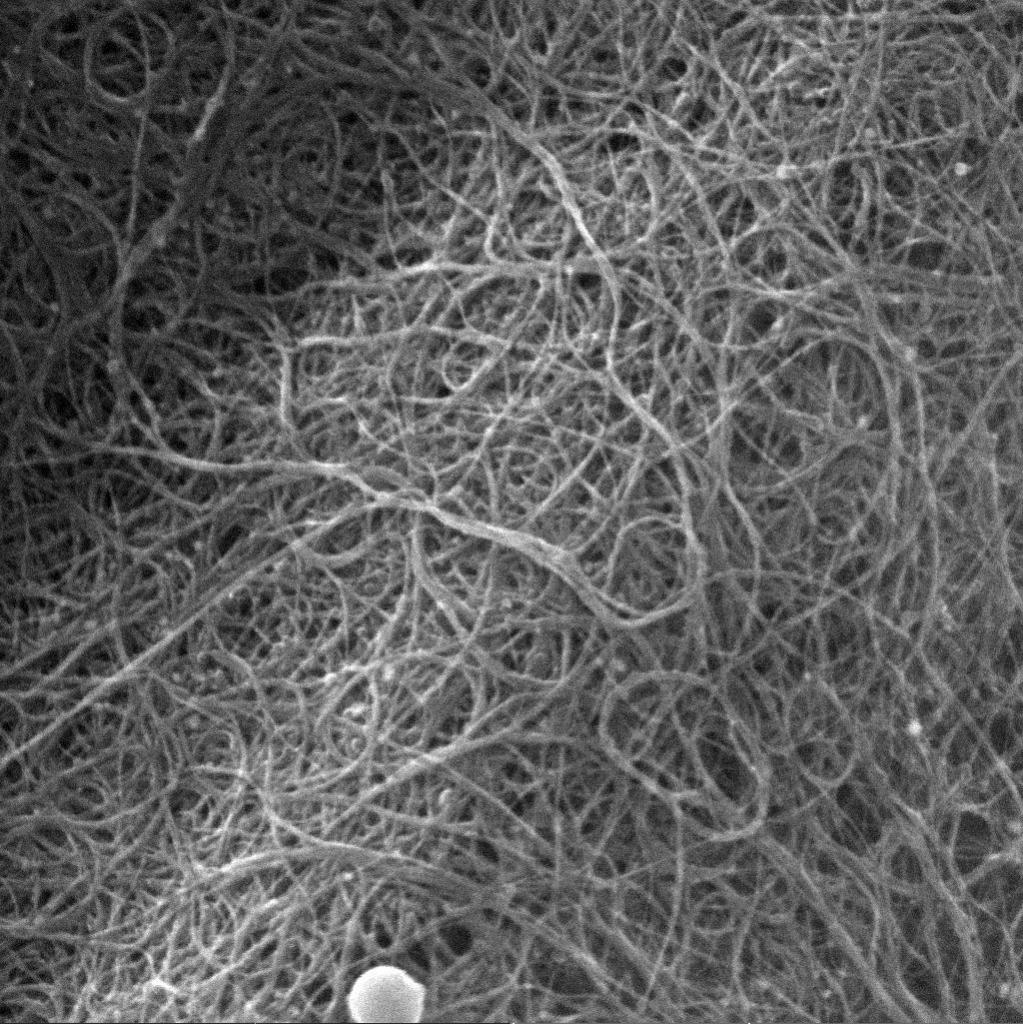

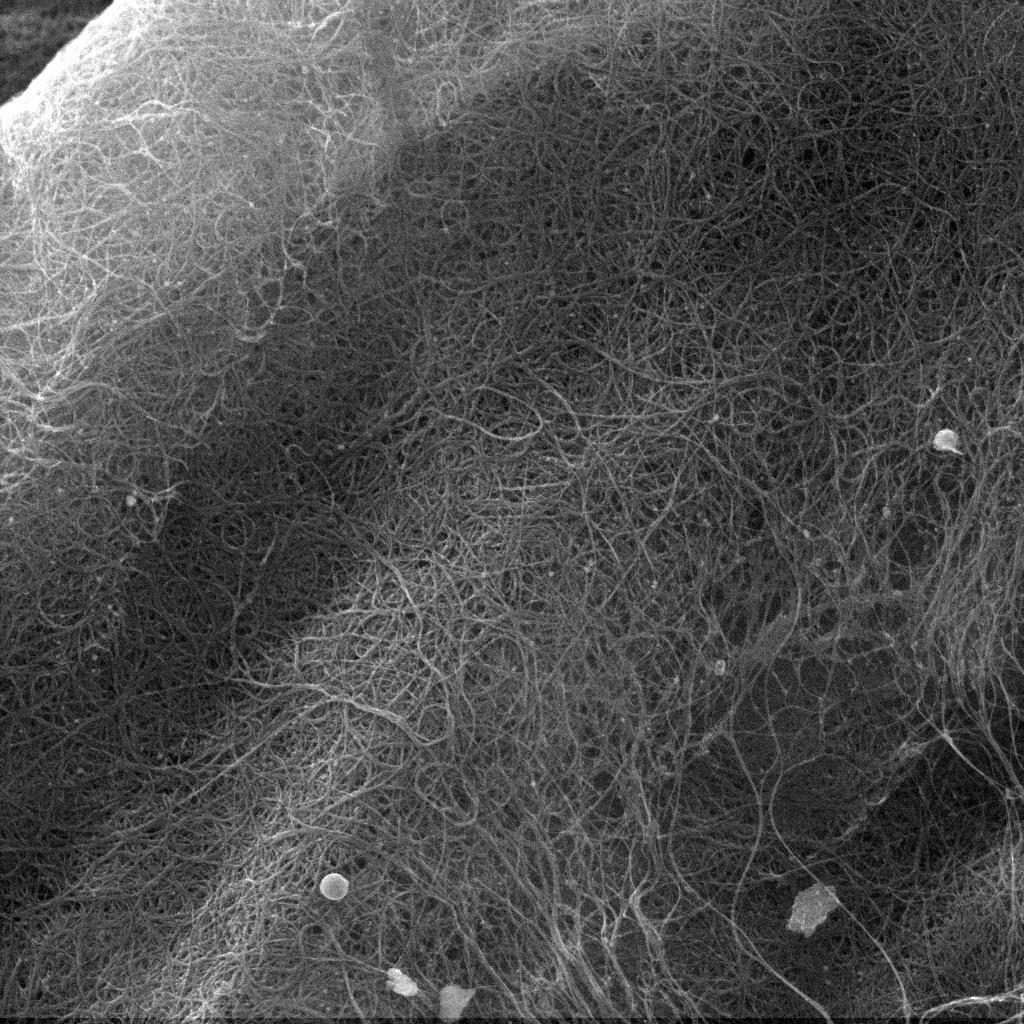

Chemical vapor deposition has become a very competitive method for production of single walled carbon nanotubes (SWCNT) in large quantities and exceptional quality.

SCIENTIFIC_VALIDATION_PUBLISHED_DATE: